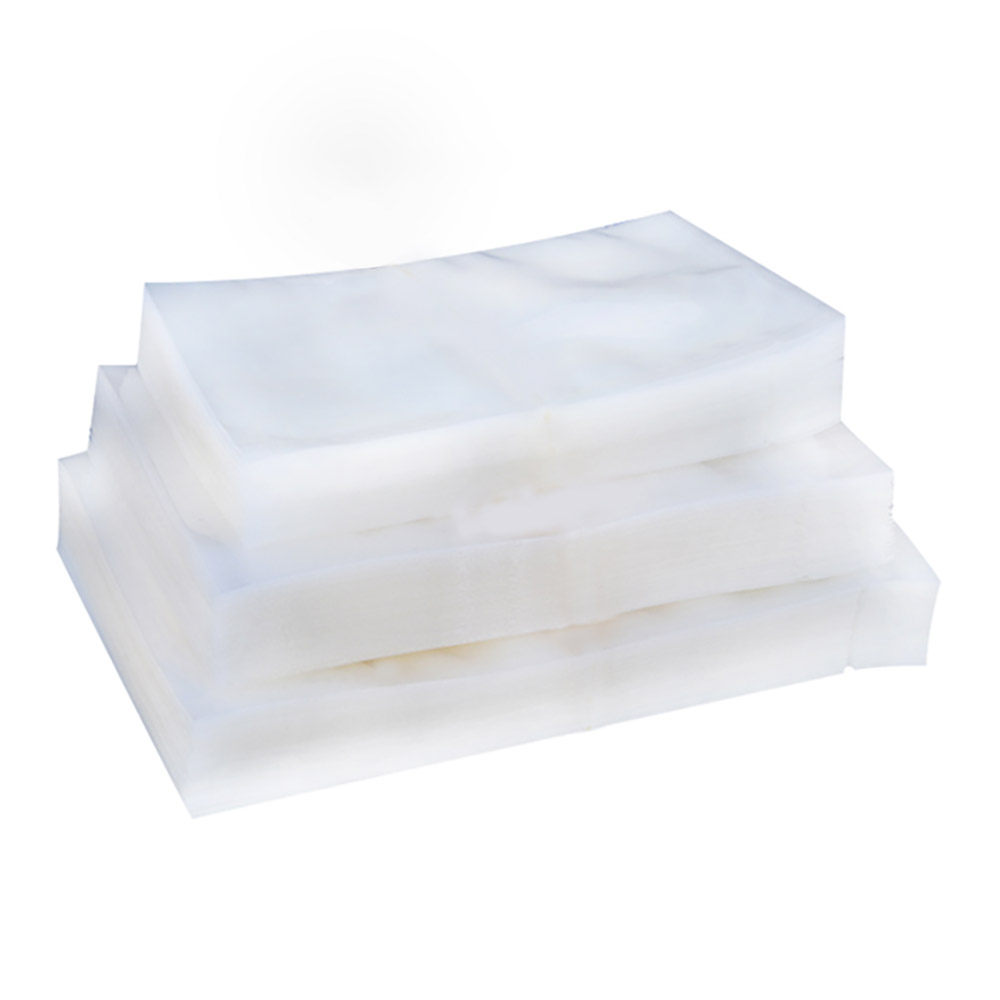

| Printing Layer | Pet, Nylon Or Pvdc Coated Material For Registered Matte; Simple Line And Texts Can Be Printed Directly On Kraft Paper. |

| Middle Layer | Middle Layer: Vmpet Or Foil For High Barrier To Extend Shelf Life Of Your Products; Pet For Pure Plastic And Economic One. |

| Heat Seal Layer | Heat Seal Layer: Pe, Cpp For Good Sealing. |

| Window | Various Types of Packaging Bags. The Shape, Position, Size Of Window Can Be Customized. |

| Printing | Cmyk, Pantone Colors, White, Gold, Silver, Metallic Color, Registered Matte Etc. Gravure Printing Up To 12 Colors |

| Delivery Time | Usually 10-50 Days After Artwork Approval And Deposit Received. |

| MOQ | Digital printing MOQ500Pcs; Gravure printing MOQ5000Pcs. |

| Design | Professional Designer Team Can Provide Free Design. |

Stand Up Pouches Custom Printed

A stand up pouch is a flexible packaging bag with a horizontal support structure at the bottom, not eaning on any support, and whether the bag is open carstand on its own.ln the flexible packaging industry, stand-up pouches are one of the preferred packaging types.Stand-up pouches have the advantages of upgrading products, strengthening the visua effect of the shelt, carrying ight, convenient to use, treshness ano

sealability, etc.We are a manufacturer with 20 stand-up pouch production and design and have served tens of thousands of customers, providing them with stand-up pouch customization services.

We have computerized high-speed printing machines, aminating machines, sliting machines, bac-making machines otvarious types and other advanced production equipment.0ur production range is from plastic bad design to plate printing to raw material lamination,badmaking, packaging, etc.

Advantages of customized food packaging bags