Vacuum bags play a crucial role in packaging in modern industries such as food, medicine, and electronics. There are many types of vacuum bags on the market, among which transparent vacuum bags and aluminum foil vacuum bags are the most common. So, what is the difference between these two types of vacuum bags, and how should we choose them?

● Characteristics of Transparent Vacuum Bags and Aluminum Foil Vacuum Bags

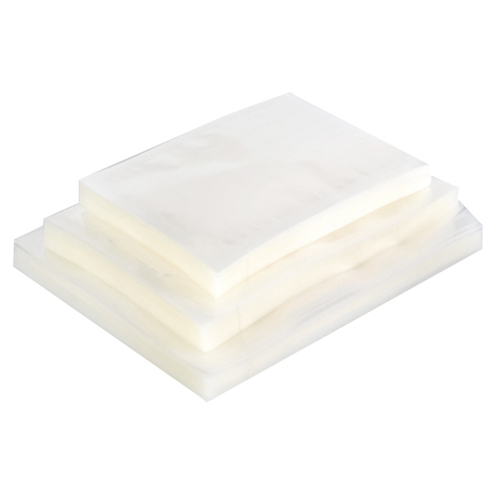

○ Transparent vacuum bag

◇ Appearance: Transparent vacuum bags have good transparency, allowing consumers to visually see the products inside the packaging, which is beneficial for enhancing the attractiveness of the products.

◇ Material: Transparent vacuum bags are generally made of materials such as polyethylene (PE), polypropylene (PP), etc., which have good toughness and puncture resistance.

◇ Scope of application: Transparent vacuum bags are suitable for products that do not require high oxygen and humidity, such as cooked food, candy, tea, etc.

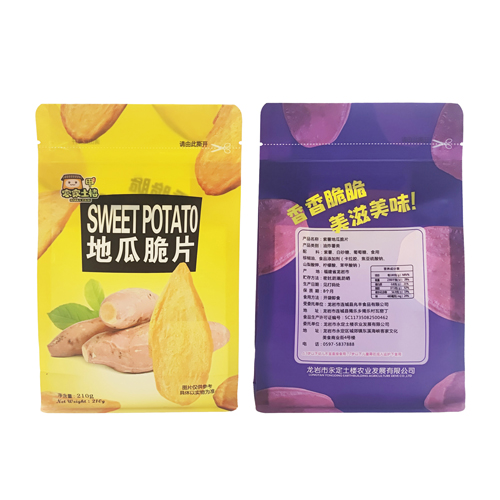

○ Aluminum foil vacuum bag

◇ Appearance: Aluminum foil vacuum bags have a certain degree of light shielding and cannot directly see the products inside the packaging.

◇ Material: Aluminum foil vacuum bag is made of aluminum foil and plastic film composite, which has good barrier properties, oxidation resistance, and high temperature resistance.

◇ Scope of application: Aluminum foil vacuum bags are suitable for products with high requirements for oxygen and humidity, such as pharmaceuticals, electronic components, cosmetics, etc.

● How to choose between transparent vacuum bags and aluminum foil vacuum bags?

○ Based on product characteristics

◇ Transparency requirement: If the product needs to showcase its appearance and enhance its attractiveness, it is recommended to choose a transparent vacuum bag.

◇ Barrier requirements: If the product has high requirements for oxygen and humidity, it is recommended to choose aluminum foil vacuum bags.

○ Based on packaging costs

◇ Transparent vacuum bags have relatively low costs and are suitable for products with certain control over packaging costs. Aluminum foil vacuum bags have a high cost and are suitable for products that require high packaging performance.

○ According to the usage environment

◇ Low temperature environment: Both transparent vacuum bags and aluminum foil vacuum bags can be used in low-temperature environments, but aluminum foil vacuum bags have better low-temperature resistance.

◇ High temperature environment: Aluminum foil vacuum bags have good high-temperature resistance and are suitable for products that require high-temperature sterilization or steaming.

○ According to transportation and storage conditions

◇ Transportation distance: For products transported over long distances, it is recommended to choose aluminum foil vacuum bags with better barrier properties to ensure product quality.

◇ Storage time: If the product needs to be stored for a long time, aluminum foil vacuum bags can better ensure that the product is not affected by the external environment.

About Us

Fujin New Materials, After Several Years Of Development, Has Developed Into A Packaging Enterprise With A Certain Scale. Our Company Integrates R & D, Design, Printing, Bag Making, Testing And After-Sales Service Into A Comprehensive Printing Company. Our Company Is Specialized In Producing Vacuum Food Bag, Aluminum Foil Bag, Opp Bags, Pe Bags, Recyclable Coffee Bag, Kraft Paper Ziplock Bags, Snacks Packaging Pouches, Stand Up Ziplock Bags, Pet Food Bag, Etc.