In the food packaging industry, rice plastic composite bags play a crucial role. It not only needs to ensure the safety of rice during transportation, storage, and sales, but also has properties such as moisture resistance, oxidation resistance, and pollution prevention. Therefore, choosing the appropriate material for rice plastic composite bags is crucial.

Durability

Durability is the first factor to consider when choosing rice plastic composite bag materials. The durability of bags is directly related to the safety of products during transportation, storage, and sales. To ensure the durability of the bag, materials with moderate thickness and high strength should be selected, such as nylon (PA), polyester (PET), etc. These materials have good tensile strength and wear resistance, which can effectively resist external pressure and friction, ensuring that the bag is not easily damaged during use.

Barrier performance

As rice is a food that is prone to moisture and oxidation, it is crucial to choose materials with good barrier properties. Common barrier materials include aluminum foil, polyethylene (PE), etc. Aluminum foil has good moisture and oxidation resistance, which can effectively extend the shelf life of rice. Polyethylene, on the other hand, has good sealing performance, which can effectively prevent the entry of oxygen and moisture, and maintain the stable quality of rice.

Material combination

Rice plastic composite packaging bags usually consist of three parts: outer layer, middle layer, and inner layer. The outer layer is made of PET or BOPP material, which is wear-resistant and tear resistant to ensure the durability of the packaging bag during transportation and storage. The middle layer is a moisture-proof barrier layer, usually made of aluminum foil film, kraft paper, nylon film, etc., which has good moisture-proof performance. The inner layer is directly in contact with the rice, usually made of food grade PE or CPP material to ensure the safety and hygiene of the rice.

When selecting materials, composite materials can also be considered. Composite rice bags are generally composed of two or more materials, which can combine the advantages of various materials. For example, some rice bags are made of PP and PE materials, which not only ensure the moisture resistance of the rice but also increase the toughness of the bags.

Other factors

In addition to the above factors, the following factors need to be considered when selecting the material of rice plastic composite bags:

Environmental friendliness: Prioritize selecting products with good environmental friendliness to reduce pollution to the environment.

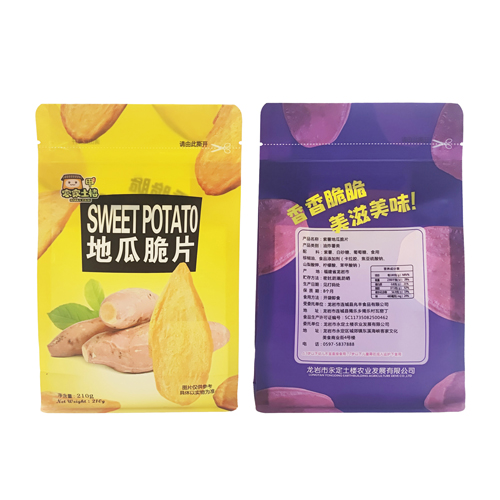

Aesthetics: The appearance of the bag is also one of the factors to consider, and beautiful packaging can enhance the attractiveness of the product.

Cost: In addition to meeting the above requirements, it is also necessary to consider cost factors and choose products with high cost-effectiveness.

Choosing the appropriate material for rice plastic composite bags requires considering multiple factors, including durability, barrier performance, material combination, environmental friendliness, aesthetics and cost. When choosing, these factors should be comprehensively considered based on the actual situation, and the most suitable material should be selected to ensure the safety and quality of rice.

About Us

Fujin New Materials, After Several Years Of Development, Has Developed Into A Packaging Enterprise With A Certain Scale. Our Company Integrates R & D, Design, Printing, Bag Making, Testing And After-Sales Service Into A Comprehensive Printing Company. Our Company Is Specialized In Producing Vacuum Food Bag, Aluminum Foil Bag, Opp Bags, Pe Bags, Recyclable Coffee Bag, Kraft Paper Ziplock Bags, Snacks Packaging Pouches, Stand Up Ziplock Bags, Pet Food Bag, Etc.