As a commodity, plastic packaging bags may occasionally have some issues that affect their use during production and use. First, let's figure out what kind of problem is a quality issue. If plastic packaging bags experience layering, breakage, or cracking before use, it can generally be considered a quality issue with the plastic packaging bag. If these problems occur during use, you can communicate with the plastic packaging bag manufacturer to jointly identify the cause of the problem. If there are problems during the storage and transportation process after packaging is completed, the causes of the problems are very complex. In addition to contacting the plastic packaging bag manufacturer for communication, enterprises using plastic packaging bags should also promptly investigate whether there are any errors or accidents during their use and transportation. Let's talk about some common problems and solutions:

Sealing problem.

Generally speaking, if plastic packaging bags have weak sealing during use, the first consideration is whether the sealing temperature and time of the sealing machine are appropriate. Too low sealing temperature and too short sealing time can lead to weak sealing of plastic packaging bags. Excessive temperature or prolonged sealing time will penetrate the film at the sealing point of the plastic packaging bag. Another reason why plastic packaging bags are difficult to seal is that the thickness of the plastic packaging bag is not appropriate. The thicker the plastic packaging bag, the harder it is to seal. Therefore, when customizing plastic packaging bags, we try to choose a reasonable thickness range instead of blindly pursuing thicker plastic packaging bags.

The problem of air leakage in vacuum plastic packaging bags.

There are many reasons that can cause air leakage in vacuum plastic packaging bags. When using plastic packaging bags, it is important to adjust the parameters of the vacuum equipment appropriately. Improper parameter settings of the vacuum equipment can lead to unable to fully complete vacuum treatment ,or excessive vacuum pressure that resulting in excessive shrinkage and rupture of the plastic packaging bag film, which leads to air leakage. Another thing to note is that during the storage and transportation of vacuum plastic packaging bags, it is important to always be careful not to let the bags be punctured by sharp objects. Sometimes, seemingly inconspicuous bumps and bumps can also cause the vacuum plastic packaging bags to break, leading to air leakage.

If this problem occurs, you should investigate the parameter settings and storage and transportation process of the vacuum equipment as soon as possible. If the problem is still not found, you can contact the plastic packaging bag manufacturer for sampling. Take out some of the remaining unused vacuum plastic packaging bags for packaging experiments. If a large number of air leaks occur, it can be considered that the problem is with the vacuum plastic packaging bags themselves.

During the use of plastic packaging bags, the following issues may sometimes be found:

Plastic packaging bags have delamination phenomenon.

Generally speaking, if there is a delamination phenomenon in plastic packaging bags, the first consideration is that the plastic packaging bag manufacturer has problems in the lamination process, which may be due to the inability to reach the lamination temperature, the problem with the lamination glue, or insufficient lamination time, etc. When encountering such problems, you need to first communicate with the plastic packaging bag manufacturer.

The sealing position or tear prone position of the plastic packaging bag is inappropriate

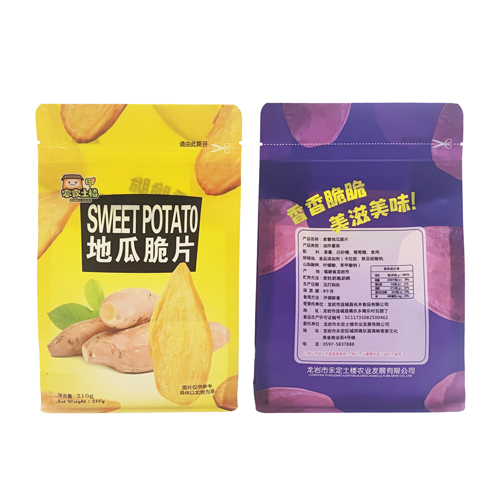

The main reason for this problem is that plastic packaging bag designers lack consideration when designing plastic packaging bags, causing product information to appear in the sealing port, resulting in incomplete display of product information, or the easily torn position being too close to the middle or both ends, which brings inconvenience to consumer use. The reason for these problems is not only due to the designer's poor consideration, but also possibly because the manufacturer did not conduct sufficient packaging experiments before customizing plastic packaging bags, providing inaccurate data to the designer, resulting in positional deviations in the plastic packaging bags designed by the designer

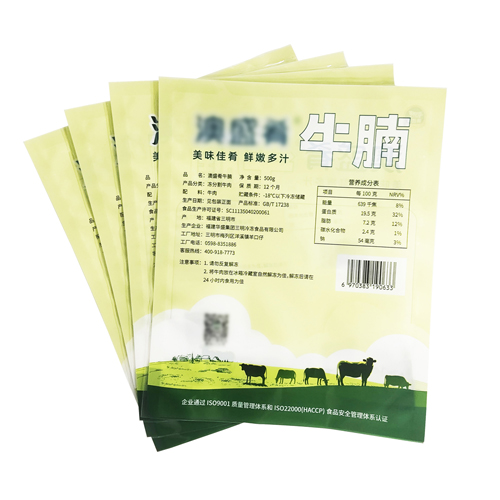

The content of plastic packaging bags does not fulfill the obligation to remind safety

The most common situation is when customers customize high-temperature resistant vacuum packaging bags made of aluminum foil material to package cooked food, food is ready to eat when opened, but some consumers still want to heat it up for consumption. If there is no indication on the outer packaging bag that "microwave heating is prohibited", it may cause safety accidents. There is also information about allergens, heating time, temperature, and so on. If plastic packaging bags should be printed but not indicated, it may cause problems. When encountering such problems, one can only abandon the use of this batch of plastic packaging bags and customize more standardized plastic packaging bags.

About Us

Fujin New Materials, After Several Years Of Development, Has Developed Into A Packaging Enterprise With A Certain Scale. Our Company Integrates R & D, Design, Printing, Bag Making, Testing And After-Sales Service Into A Comprehensive Printing Company. Our Company Is Specialized In Producing Vacuum Food Bag, Aluminum Foil Bag, Opp Bags, Pe Bags, Recyclable Coffee Bag, Kraft Paper Ziplock Bags, Snacks Packaging Pouches, Stand Up Ziplock Bags, Pet Food Bag,Etc.